CHOOSING CORRECT LIMITS

When we have our vibration readings taken correctly from machinery, it is time to assess whether those values are high or not. Without detailed spectrum analysis we cannot say anything about real condition of machinery, however it is a good practise to firstly evaluate if vibrations are excessive. There are different ways how we can approach this.

1. ISO standards

International Organization for Standardization is recognizable all around the world. It provides us a lot of standards with which we can compare our production, management, services, supplies etc. There is a very wide range of different standards describing huge range of activities. Of course, ISO standards cover also subject of vibration diagnostic. Apart from standards for vibration of machinery we have also ones covering for example vibrations of buildings or vibrations affecting comfort. But those are not the subject of this article. Most known family of ISO standards for vibration diagnostic is “ISO 10816/20816 Mechanical vibration — Measurement and evaluation of machine vibration”. We have overall standard ISO 20816-1 and standards specified for exact types of machinery like 10816-7 covering rotodynamic pumps. That is why, firstly we need to choose correct standard. This usually done based on knowledge about type and application of our machinery. For example, electrical motors are covered in: “ISO 10816-3 Mechanical vibration — Evaluation of machine vibration by measurements on non-rotating parts — Part 3: Industrial machines with nominal power above 15 kW and nominal speeds between 120 r/min and 15 000 r/min when measured in situ”. ISO standards usually have tables with guidelines for vibration limits.

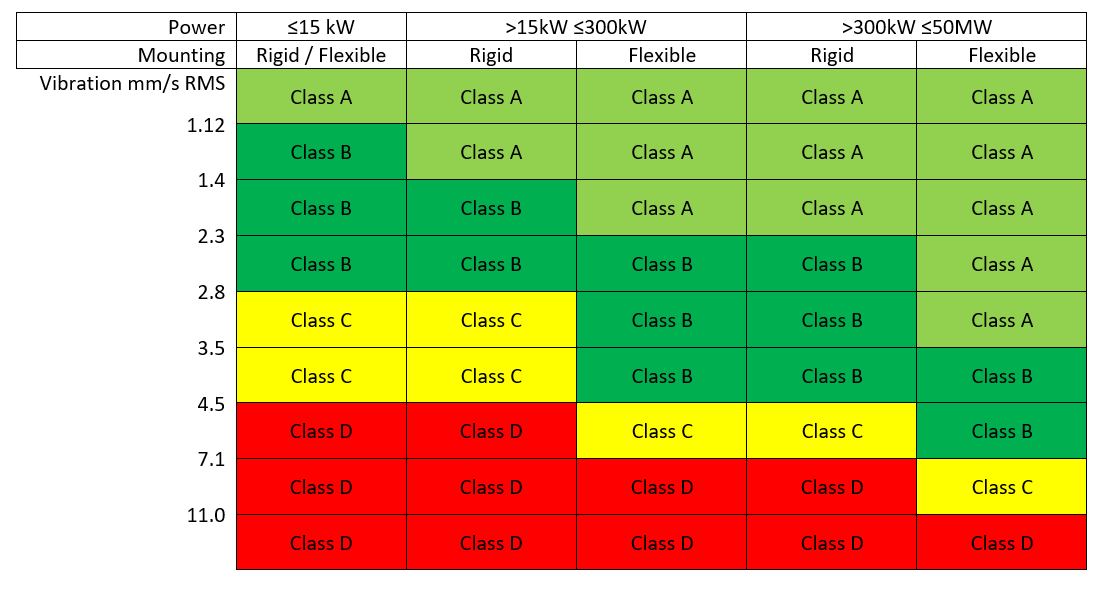

Fig.1 Vibration limits based on ISO 20816-1:2016 and 10816-3:2009

In most cases we will need some technical data like power, mounting type, rotating speed to choose correct limits. We just need to go through tables and find information that will be most accurate for our specific machinery.

2. Class society regulations

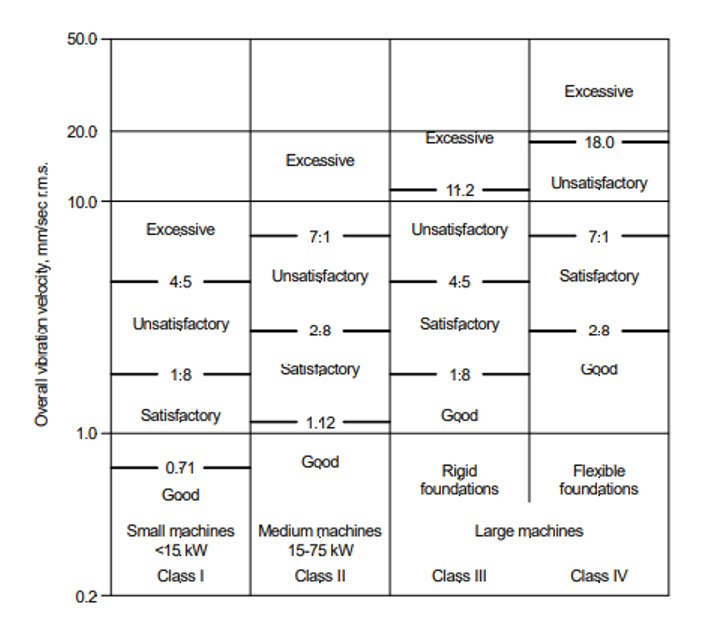

Many Class societies have their own regulations for condition monitoring. While ISO standards are still fully acceptable, in some cases we may want to use Class regulations. Choosing limits from Class rules is very similar to working with ISO standards. We also just need to find appropriate table and based on our machinery technical details find limits that will be the most accurate. From our experience Class rules for vibration are usually not so well organized as ISO standards, but with bit of work we will find what we are looking for.

Fig. 2 Example of vibration limits from Lloyd’s Register guidance notes.

3. Makers recommendations

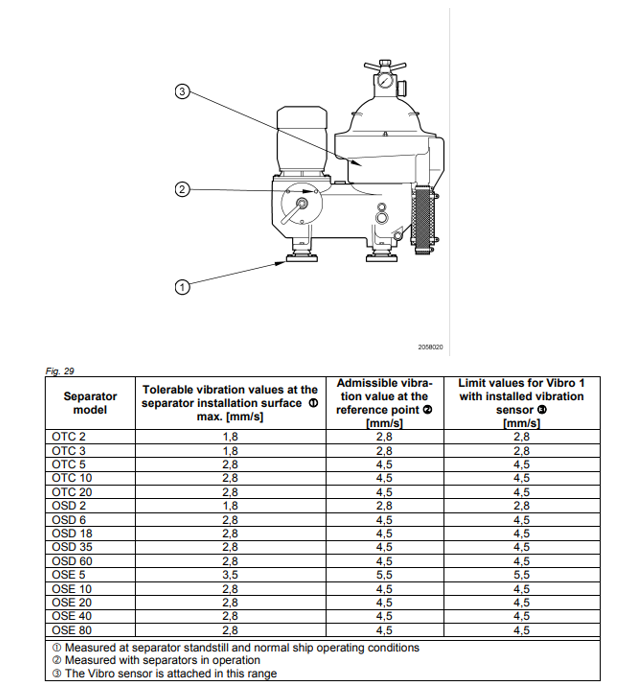

Quite often maker of our machinery will introduce its own limits. Those should be more accurate than ones in ISO standards and Class rules. They are established not just for specific type of machine, but for exact models from makers inventory. Maker usually conducts tests on his machinery to determine vibration values that most probably would not cause any failure. If available makers recommendations should be used instead of ISO standards or Class regulations. If we cannot find such limits in manuals, we can always contact maker and ask about them.

Fig. 3 Vibration limits for GEA Westfalia separators.

4. Statistical limits and trend analysis

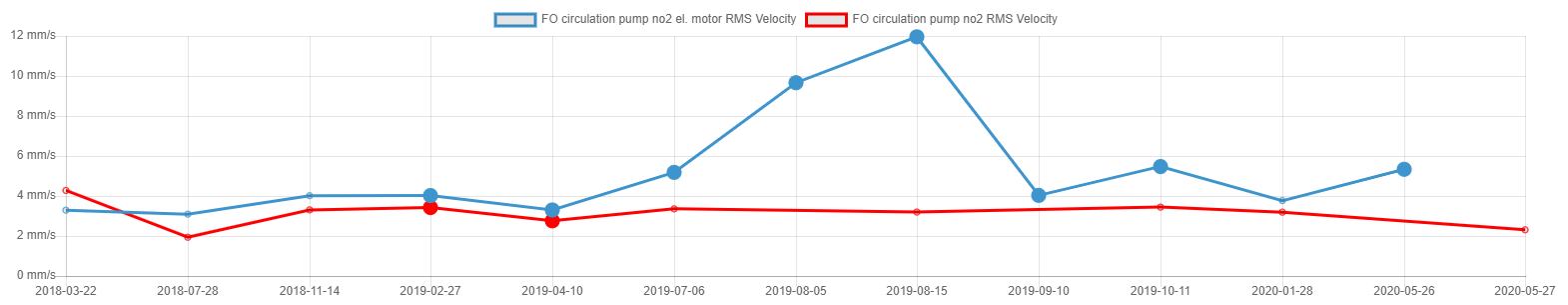

The most accurate vibration limits for our machinery would be those based on knowledge about our exact machinery mounted in exact way, near other specified machinery, working in exact conditions. Even if we have limits from maker for our particular model of machinery, we can have different vibration readings from it, because of setting in which it operates. If we have for example pump placed near Main Engine, then maybe vibrations will be higher than makers recommendations when ME is running. It does not mean that fault is developing right away. External vibrations are for example acting on bearing in different way than vibrations transmitted from the shaft. When we have considerable history of vibration measurement, we can say with confidence what are the actual values which would start to indicate issue with our machinery. This is done in trend analysis and by establishing statistical alarms. In trend analysis, rather than observing what is the level of vibration, we are looking if those vibrations are increasing and how quickly. If we notice constant rising of our vibration signal, we can suspect that maybe some fault started to develop.

Fig. 4 Example of maintenance performed based on trend results

To establish statistical limits, we are gathering all data that we consider as baseline and we perform mathematical calculation to get most accurate limits. For example, we are calculating average value and standard deviation. Alarm is set to average plus 3 times standard deviations. If we have some identical machineries working in very similar setting than we can calculate statistical alarms for all of them. However, it is very important to correctly specify our baseline data. If use vibration values from measurements on faulty machinery, then our limits will not be accurate. We can use readings taken on newly installed machinery, or after overhaul when we are certain about condition of our machine. Trend analysis and statistical alarms are the best option to determine whether vibration values are excessive or not.

ALLWAYS PERFORM DETAILED ANAYLIS TO BE SURE ABOUT CONDITION OF MACHINERY.

Even if we are using trend analysis and statistical limits, we need to perform detailed analysis to be sure about condition of machinery. Not only it means to determine if vibrations are coming from machinery or external source but also knowing what exact faults is present if we know that machinery is really in bad condition. We should not limit ourselves to just replacing bearings. If issue is with misalignment then it should be assessed first.

Patryk Brząkała

Senior Reliability Engineer

References:

[1] ISO Standard 20816-1 “Mechanical vibration — Measurement and evaluation of machine vibration - Part 1: General guidelines” First edition 2016-11-15

[2] ISO Standard 10816-3 “Mechanical vibration — Measurement and evaluation of machine vibration - Part 1: Industrial machines with nominal power above 15 kW and nominal speeds between 120 r/min and 15 000 r/min when measured in situ” Second edition 2009-02-01

[3] Lloyd’s Register “Ship Vibration and Noise Guidance Notes” 07.2006 Revision 2.1

[4] GEA Westfalia Separator Group “Installation Instruction for Separators No. 2058-9601-020” Edition 0211

[5] James E. Berry P.E. Technical Associates Of Charlotte, P.C. “Analysis I How to implement an effective condition monitoring program using vibration analysis” Second Edition 06.1997