HOW TO DETERMINE SOURCE OF VIBRATION?

How do you know if measured vibration is not coming from machinery nearby? How can vibration analysis be effective if we have a lot of influence coming from environment? Those are just examples of many questions that we receive about vibration measurements on board of vessels. Those are very sensible questions, especially in marine industry.

When we are taking vibration readings, we are measuring all forces acting on our sensor, whether they are generated by machinery, transmitted from environment, coming from rocking of the sensor due to improper mounting or even forces from slamming accelerometer on machinery, if we start measurement too soon. Yes, we are performing some filtration on machinery discarding some low frequencies that might have come from device measuring range limitations and some high frequency that are not in interest, but measured signal is still just a sum of all vibrations.

There are 2 main ways in which we can present our vibration results:

- Overall value

- FFT spectrum

There are also of course time waveform, orbits, and other plots but they are a bit more complicated and will be not discussed in this paper.

Overall value is just single numeric value, which describes severity of measured sum of vibration. We specify unit, frequency range, whether it is RMS, 0-Peak or PEAK but that is all. There is no information if signal is coming from one frequency or whether there are many sources.

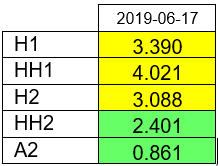

Below are presented overall values measured on HT FCW pump el. motor. Those are Velocity RMS in mm/s in frequency range 10-1000Hz

Values are slightly increased but nothing alarming. In the next measurement we received following results

We can see increase in vibrations over two times. What is the reason for that? Is the machinery starting to fail? From those values we can assume that indeed something is going wrong. But before we perform maintenance, we will also investigate FFT spectrum.

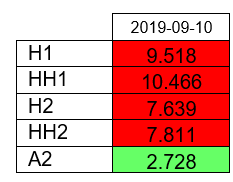

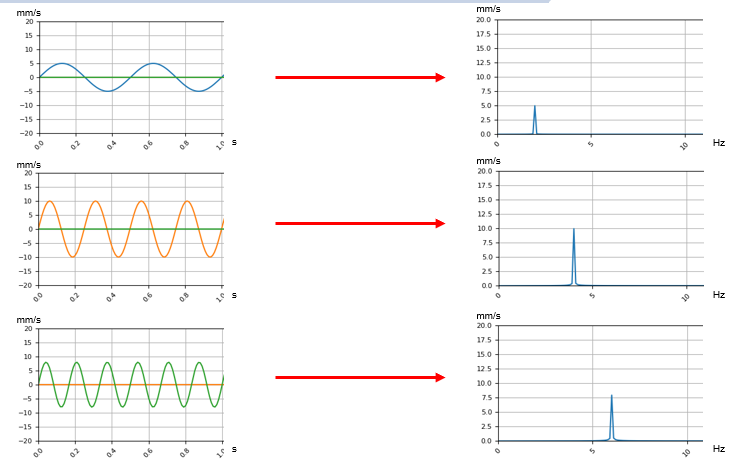

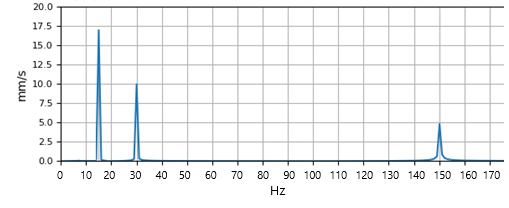

FFT spectrum presents vibration signal on a graph with amplitude on y axis and frequency on x axis. For example, below vibration signal is combination of 3 different (with different frequency) signals:

It is extremely hard to see those 3 signals on sum vibration (on left). FFT presents all individual signals from sum vibration.

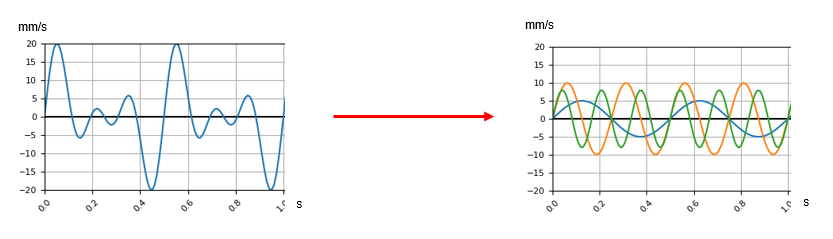

Each individual signal is a sine wave. All sine waves are presented on graph with frequency on x axis and amplitude on y axis.

Then individual signals are combined to one graph that represents sum of vibration.

Now, on FFT spectrum, it is easy to see that sum vibration is combination of 3 signals and that highest amplitude is in middle signal (4Hz).

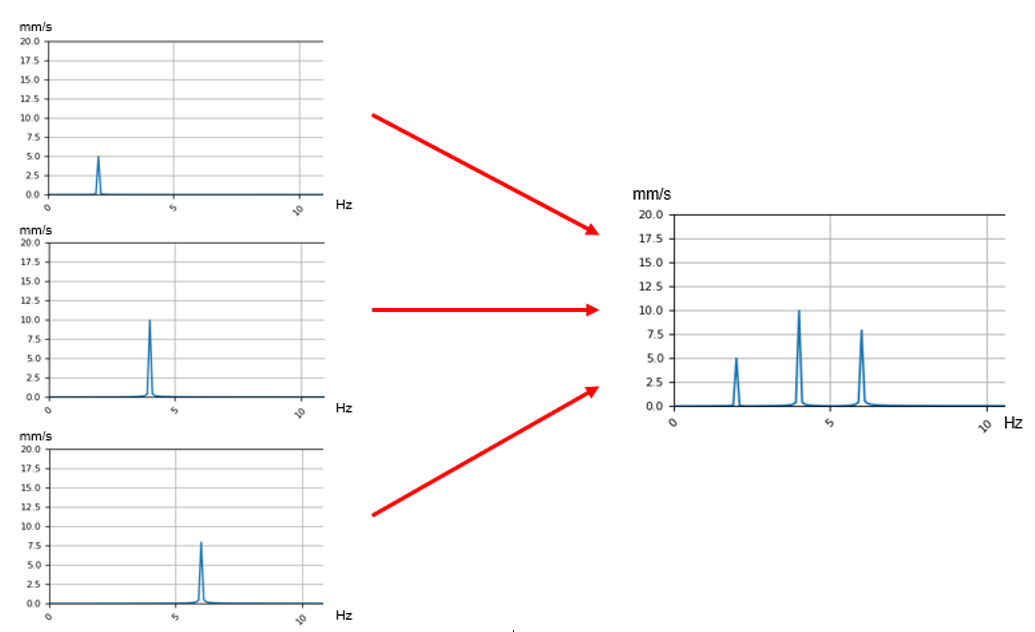

This is important because we can associate specific frequencies with specific sources of vibration.For example: We have electric motor running at 1800rpm driving centrifugal pump with 5 vanes on impeller.

Frequency associated with el. motor in Hertz will be: 1800 rpm / 60 = 30Hz.

Frequency associated with impeller will be: 30Hz * 5 = 150Hz.

Now from FFT spectrum we can read which frequency (and associated with it fault) have highest amplitude.

As you can see highest signal is at 30Hz so we can say that highest influence on sum vibration has electric motor.

Let us now imagine that we have near generator running with 900rpm.

Frequency associated with this generator will be: 900rpm/60 = 15Hz.

Now highest signal is present at 15Hz. Through FFT analysis we say that high vibration signal comes from environment and not machinery itself.

We know how signals coming from ME or sea influence will look on FFT spectrum. We have a lot of experience in determining actual source of vibration.

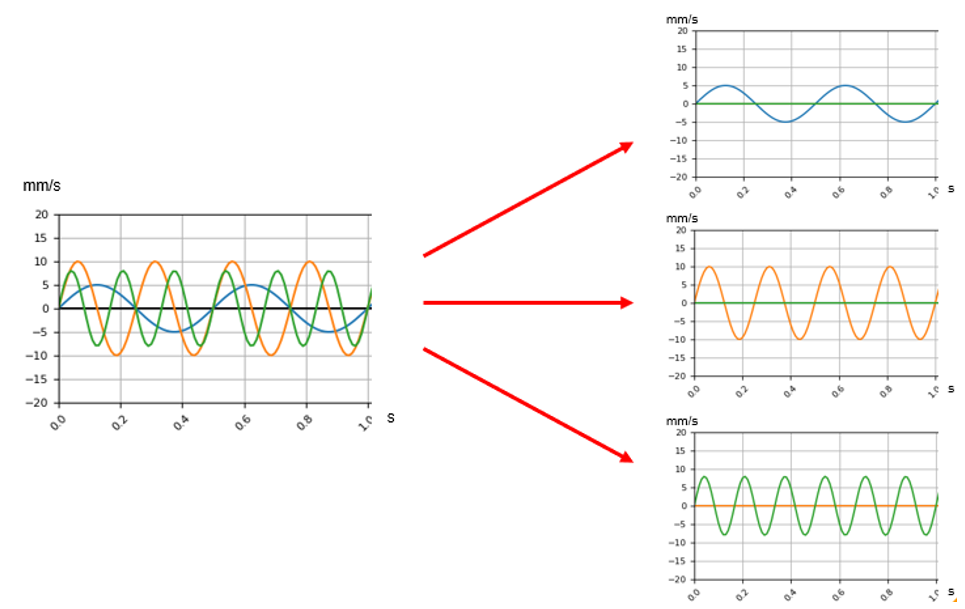

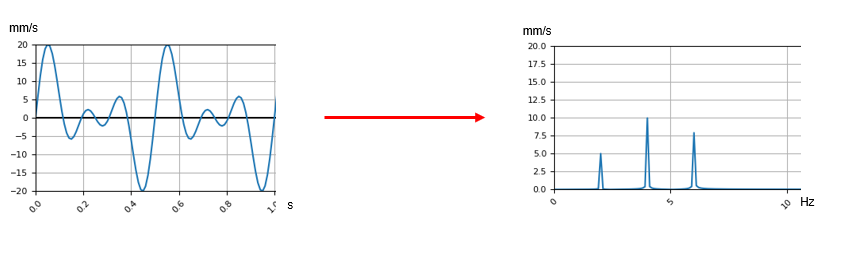

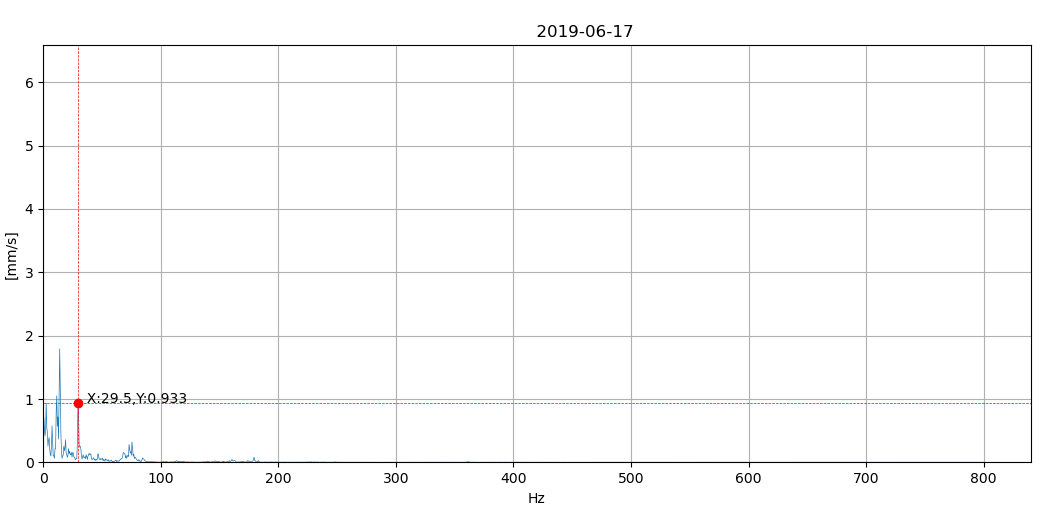

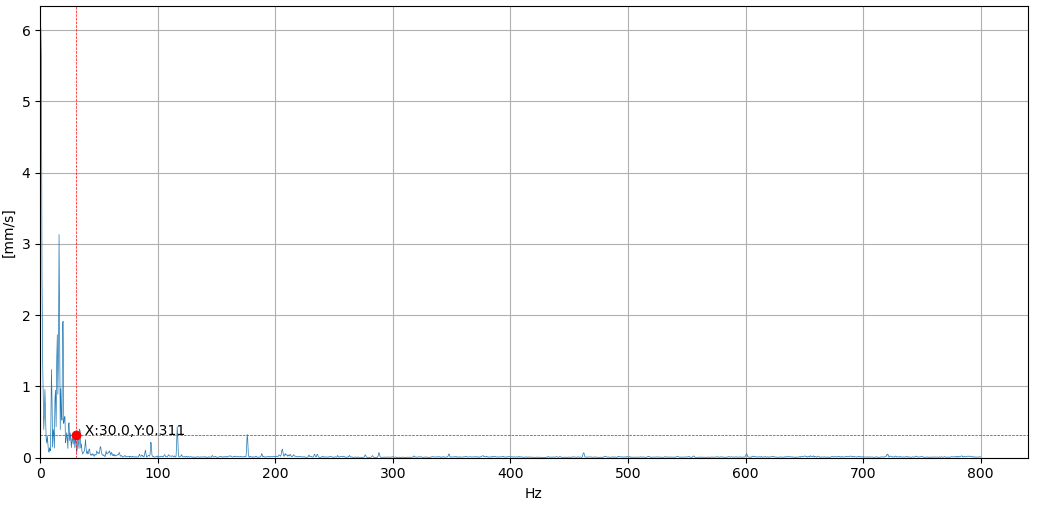

Going back to our HT FCW pump el. motor example. FFT spectrum from our first measurement taken on 17.06.2019 looks like that:

We see peak coming from rotating speed of electric motor (at 29.5 Hz) and increased signal at lower frequency not associated directly with electric motor rpm.

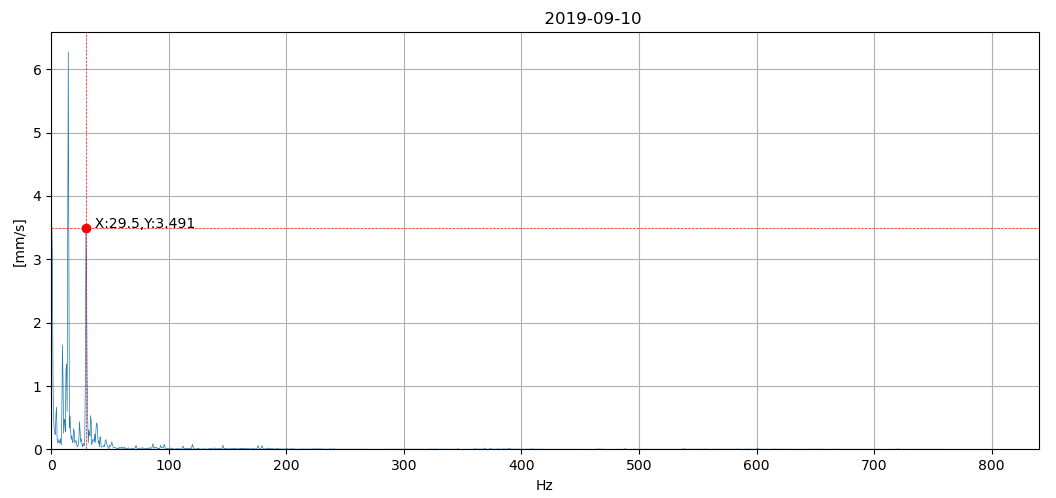

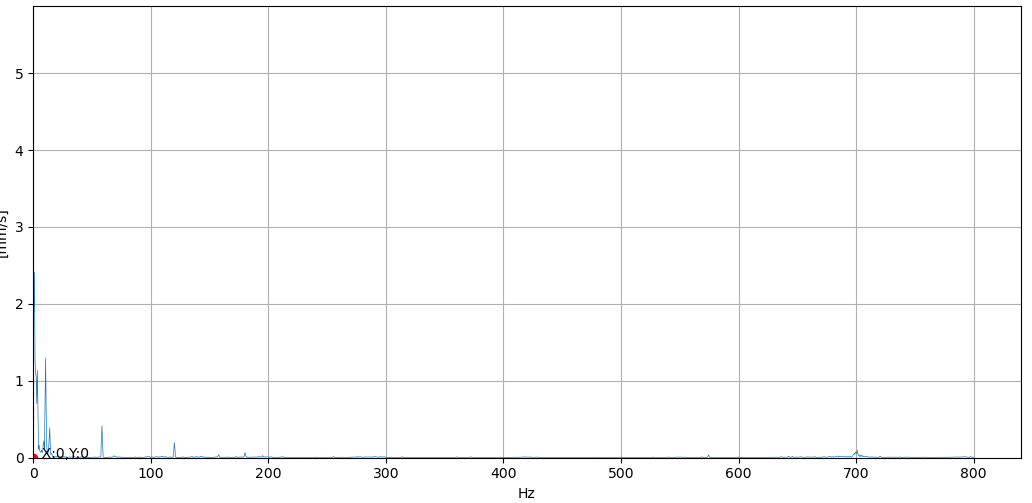

On FFT spectrum from next measurement, we see increased signal from electric motor, however much higher amplitude is present on lower frequency. This is signal coming from environment. It was confirmed that first measurement was taken during port stay and second during voyage.

Signal coming from environment will have distinctive look on different machinery. It takes a lot of experience to be able to accurately spot such signal. Info Marine analysis team spends thousands of hours analyzing spectra to build that experience and become familiar with its characteristics. Thanks to this we can determine actual source of vibration in measured signal.

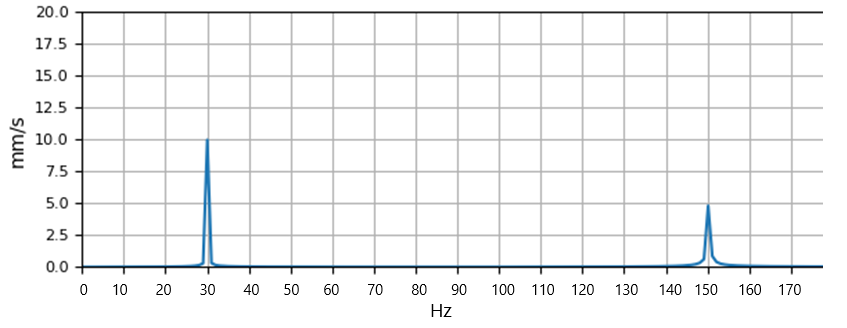

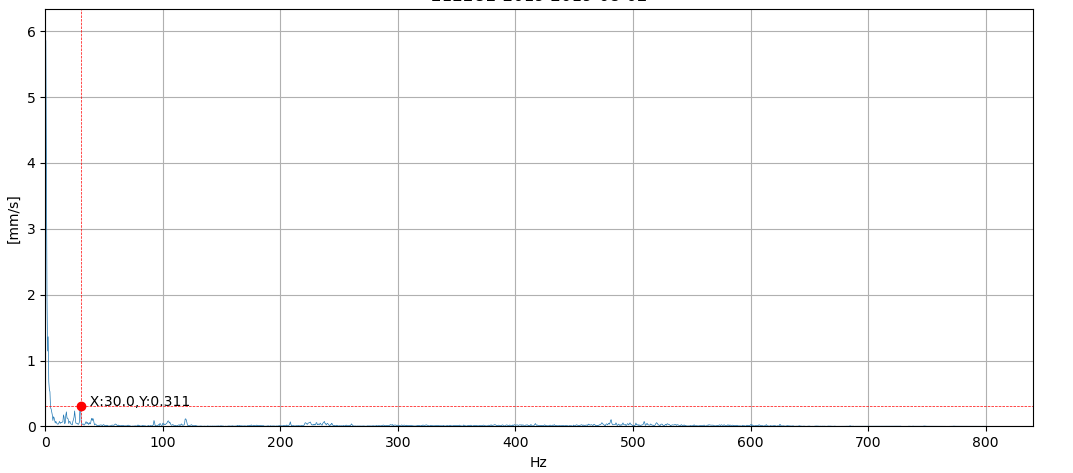

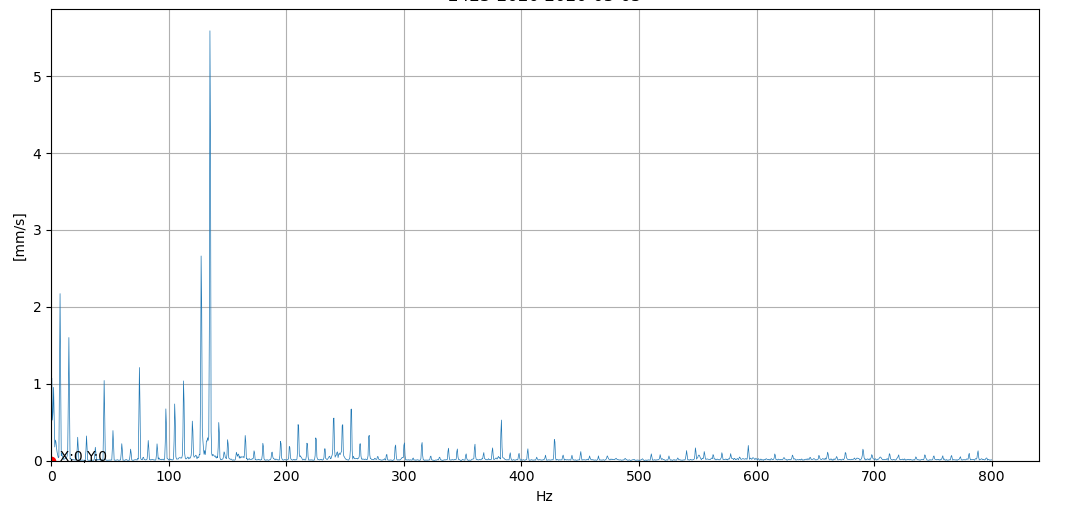

Please find some more real examples of environment signals:

Bilge pump el. motor during port stay:

Bilge pump el. motor during voyage:

GE feeder pump el. motor with nearest generator stopped:

GE feeder pump el. motor with nearest generator running:

Patryk Brząkała

Senior Reliability Engineer

References:

[1] James E. Berry P.E. Technical Associates Of Charlotte, P.C. “Analysis I How to implement an effective condition monitoring program using vibration analysis” Second Edition 06.1997

[2] Jason Mais SKF USA Inc. “Spectrum Analysis The key features of analyzing spectra” 05.2002

[3] M.Luft, PRUFTECHNIK AG “Machinery diagnosis: Quick and easy through FFT analysis” 05.2010

[4] John S. Mitchell “Machinery analysis and monitoring” Second Edition 1993